Technical Documentation

Low-temperature regeneration desiccant air Handling unit

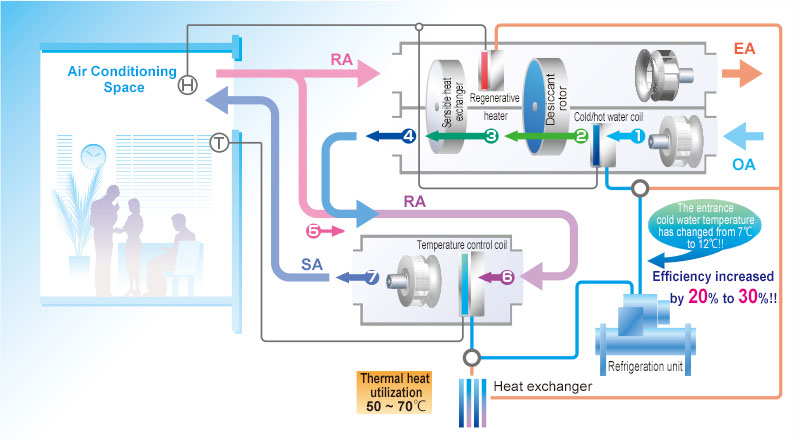

Previously, a high regeneration temperature of around 100°C was required for the desiccant rotor, but by using a new polymer adsorbent as the desiccant material, it is now possible to regenerate efficiently from 40°C. As a result, it is now possible to effectively utilize low-temperature exhaust heat (40°C to 80°C) that was previously discarded, and perform dehumidification (latent heat treatment).

A desiccant air conditioner that can be regenerated even with low-temperature exhaust heat thanks to a rotor made of a new material

Importance of dehumidification

In Japan, where temperatures are high and humidity are high, efficient dehumidification (latent heat treatment) is an important key to energy conservation.

The Kyoto Protocol came into effect in February 2005, and greenhouse gas emissions are now required to be reduced by 6% from the 1990 standard. In response, the Ministry of the Environment led a campaign called "COOL BIZ" to encourage people to set the indoor temperature at 28°C when air-conditioned by dressing appropriately. However, if humidity is not controlled and the temperature is set at 28°C, many people will feel uncomfortable. Humidity control is also an important factor in popularizing the "air-conditioning setting temperature of 28°C."

Humidity control also leads to "food preservation," "safety during processing," and "improved productivity of industrial equipment.

Types of desiccant rotors

The main types of desiccant rotors are those with polymer adsorbents suitable for low-temperature regeneration, and those with silica gel and zeolite adsorbents suitable for high-temperature regeneration. Research into lowering temperatures is still being actively conducted.

Sorption and adsorption

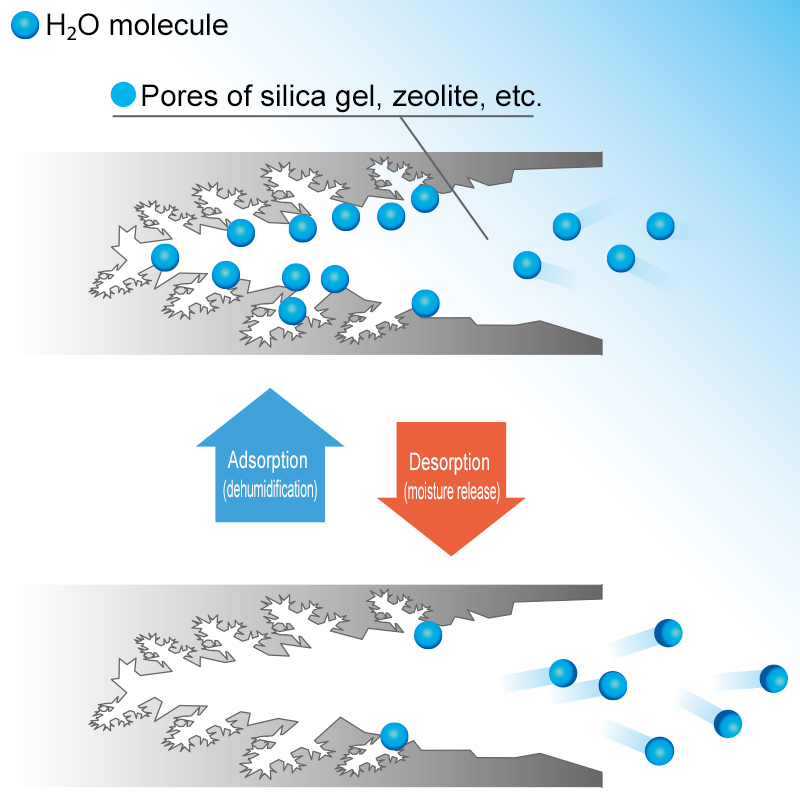

Silica gel agents and zeolite agents, which are suitable for high-temperature regeneration, remove moisture from the air by adsorption.

Dehumidification occurs when water molecules enter the pores (concave portions) on the rotor surface. When heat is applied, the adsorbed water molecules become active and jump out of the pores, causing desorption.

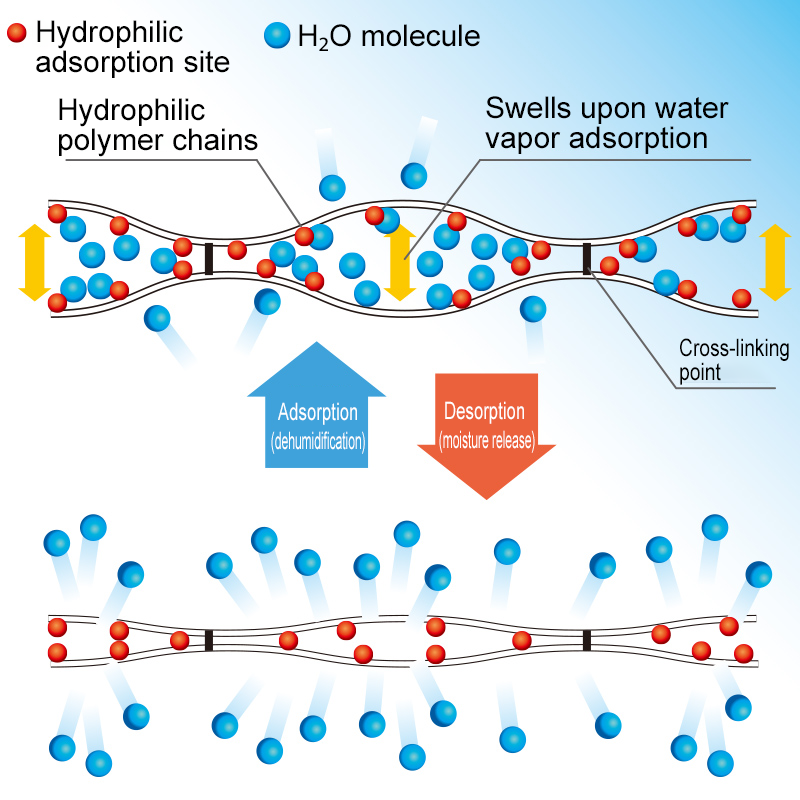

Polymer adsorbents, which are suitable for low-temperature regeneration, dehumidify by sorption, which combines adsorption and absorption. Sorption is when water molecules bind to hydrophilic polymer chains, and the polymer cross-linked body swells and deforms with the cross-linking points as a fulcrum, trapping the water molecules like capillary condensation. Water molecules adsorbed to the polymer cross-linked body are desorbed as the polymer cross-linked body shrinks at low temperatures of 40℃ to 80℃.

Adsorption mechanism

Movement on the psychrometric chart in a desiccant Air Handling Unit

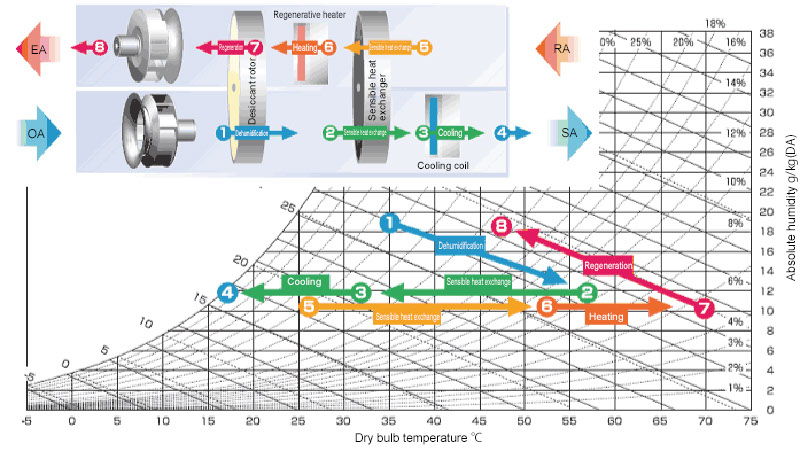

In a desiccant air conditioner, there are two flows, the dehumidification side and the regeneration side, which are in opposition to each other.

On the dehumidification side, when the air to be dehumidified ① passes through the desiccant rotor, the absolute humidity decreases due to the dehumidification effect, and at the same time the temperature rises due to the heat of adsorption. In addition, due to the energy transfer by the rotating rotor, on the psychrometric chart, it moves slightly above isenthalpy to state ②. Since ② is a high-temperature, low-humidity state, the temperature is effectively lowered by the sensible heat exchanger to state ③, and finally it is cooled (temperature regulated) to the discharge temperature ④ as necessary.

On the regeneration side, the regeneration air ⑤ exchanges sensible heat with the desiccant rotor outlet air ②, and it reaches state ⑥. After that, it is raised to ⑦ according to the required amount of dehumidification, and finally passes through the desiccant rotor to state ⑧.

The greater the difference in relative humidity between the desiccant rotor inlets ① and ⑦, the greater the dehumidification capacity. Therefore, a large dehumidification capacity can be achieved by increasing the regeneration temperature ⑦ or by cooling the air ① at the treatment inlet to increase the relative humidity.

Advantages of desiccant air conditioners

General air conditioning

Humidity control is possible by utilizing waste heat and unused energy, so appropriate humidity management can be achieved without reheating. In addition, indoor comfort is improved by not cooling too much.

Since latent heat and sensible heat can be treated separately, sensible heat can be treated with relatively high-temperature cold water (12°C), which increases the COP of the chiller and improves the "air conditioning system efficiency.

Semiconductor factories

- 1.Precise humidity control is possible.

- 2.Previously, steam was used for regenerated heat, but with the ability to regenerate at low temperatures, it is now possible to use cold and hot water to maintain low humidity.

- 3.Since latent heat and sensible heat can be treated separately, sensible heat can be treated with relatively high-temperature cold water (12°C), improving the COP of the refrigerator.

- 4.Waste heat and unused energy can be used to treat latent heat, and improving the COP reduces CO2 emissions.